It is a traditional American manufacturer of glazes and paints for ceramics. In case of interest, other products of the concern / tools, Brent circles ... / will also be gradually introduced.

... Amaco-liquid glazes and underglazes

Safety:

Before using download safety data sheets: www.propec.cz/en-bezpecnostni-listy-amaco

Notice:

If you want to use glazes to your business, the symbols for the individual glazes will help you, but that's not enough! Utility manufacturers must have their products tested in a certified testing laboratory. The safety of the product for utility depends on the properties of the top glaze, mass, firing temperature and possible contamination.

Basic information:

For easier orientation, we present an orientation table of converting the Orthon scale to ° C (thermometers 150 ° C / h).

For example, for glazes with the recommended firing CONE 5, the temperature corresponds to 1182-1196 ° C. A very slow temperature rise above 1050 ° C is recommended. If this is not possible, for faster firing, try raising the temperature to 1220 ° C and lasting longer, for example, 30 minutes.

Tabulka převodu

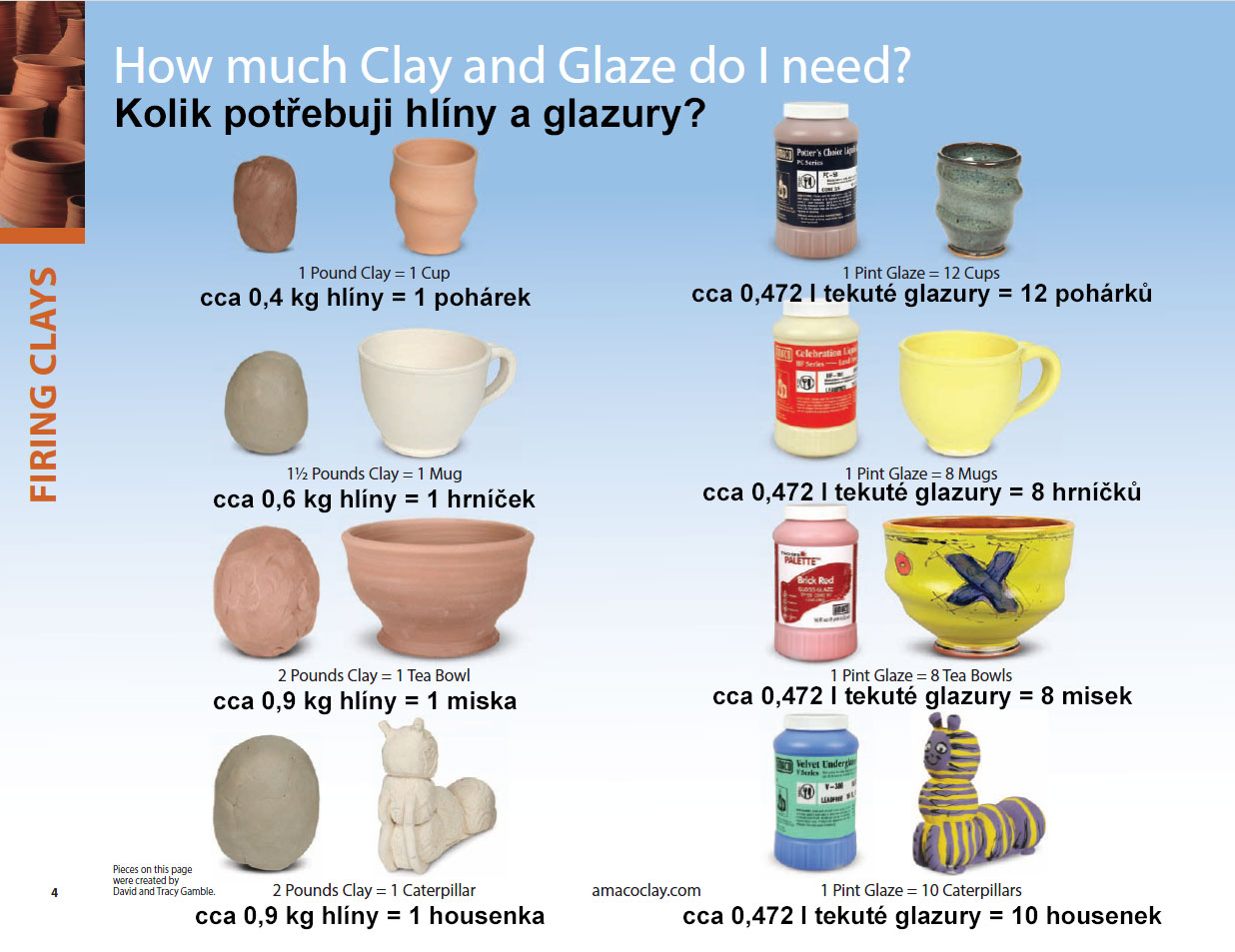

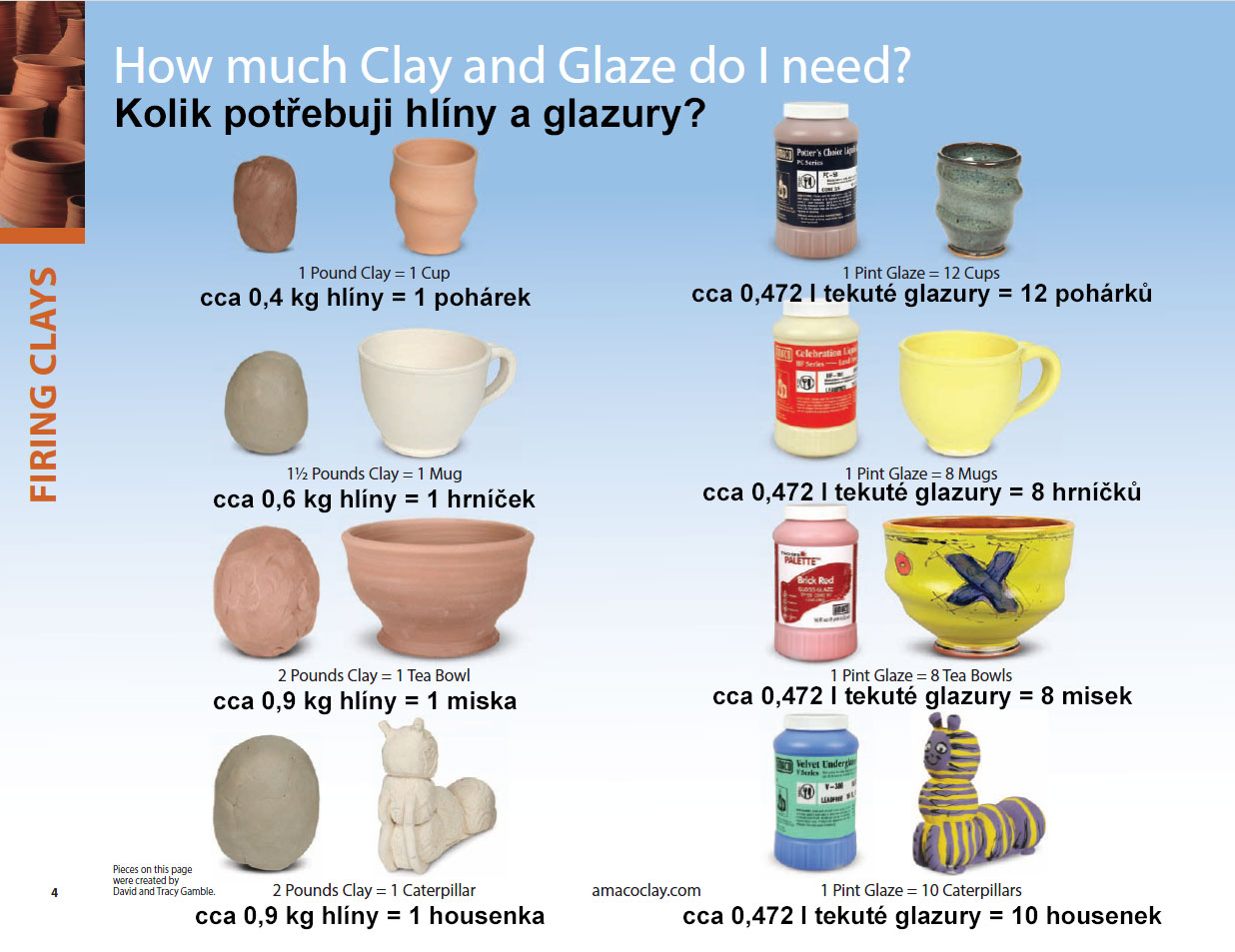

Kolik potřebuji hlíny a glazury?

Rady a nápady z youtube kanálu Amaco

BACK

... Amaco - powder glazes

AMACO dry glazes

AMACO dry glazes are based on the same popular formulas as the AMACO brushing glazes, in a dipping format to speed up studio production. Please read through the instructions entirely before mixing and using the glaze.

MATERIALS

Make sure to assemble all the needed materials before mixing your glaze. The dry glaze is meant to be mixed all at once, so instructions are for the entire bucket of glaze, not small quantities.

- Dry glaze

- Bucket (included)

- Instructions

- Dust mask / Respirator (NIOSH approved)

- Mixer (prop style mixer blade attachment on drill or stand mixer)

- 4 gallons Distilled water (final glaze will use 2.7 to 3.5 gallons)

- Gram scale (recommend digital scale with 2 decimal places)

- Small container for weighing glaze

- Test tiles

- Underglaze and applicator or underglaze pencil (for labeling test tiles)

- OPTIONAL: 30 mesh sieve/ screen

MIXING INSTRUCTIONS

- Put on NIOSH approved respirator. (Wear whenever dust from glaze is present.)

- Add two (2) gallons of water slowly to dry / powder glaze in the provided bucket.

- Let water soak into dry glaze for 20 minutes to avoid excess dust.

- Use mixer to blend materials. Blend for 30 minutes at medium to high speed.

- OPTIONAL: Pour glaze through 30 mesh sieve (sieving is not recommended for PC-29, PC-52, and PC-59).

- Let glaze sit overnight (12 hours minimum) to fully hydrate glaze materials.

- Use mixer on high speed to reblend for 10 minutes. (If glaze has hard-panned go to Troubleshooting Guide on page 2).

- Check Specific Gravity (see specific gravity instructions on page 3).

a) Compare the specific gravity to the chart on page 4.

b) If the specific gravity is HIGH, add water in small increments and recheck.

c) If the specific gravity is LOW, let the glaze sit overnight (do not remix) and remove some waterfrom the top of the glaze and set aside (in high iron glazes the water may be red but will not cause loss of glaze materials).

- Once Specific Gravity is within the recommended range, your glaze is ready to use. (SUGGESTION: notate the specific gravity and date mixed on the bucket.)

- Mix (with a mixer or a large whisk) before each use to ensure the glaze is homogenous. Periodically recheck specific gravity and adjust accordingly.

BEFORE USING YOUR GLAZE

Once glaze is mixed and specific gravity is within the recommended range, test your glaze to find the length of dip needed for the appropriate thickness. Most AMACO glazes are meant for a single 5 second dip in glaze, but always test your dipping glaze before applying to a large amount of ware. Test by marking three or more tiles (with underglaze or an underglaze pencil) for 3 seconds, 5 seconds, and 7 seconds. Mix well before dipping. Using a timer, dip top of each tile in glaze, holding tile in glaze for the marked amount of time. Fire to the appropriate cone. Find the tile with the desired application of glaze. If all results are too thin or too thick, and your specific gravity is within the recommended range then the length of time the piece is dipped may need to be adjusted. It is not recommended to alter the glaze beyond these instructions. Too much water can cause the glaze to settle or “hard-pan”, too little water can result in a glaze that is too thick, and may run or crawl.

DIPPING INSTRUCTIONS

Always mix glaze from bottom of bucket before using. The glaze may settle if it’s been sitting for a long time. It’s normal for glazes to settle soft (thicker at the bottom but can be mixed easily) over time. Check specific gravity for your glaze before using if it’s been sitting for an extended period of time. Dip ware into glaze for the appropriate number of seconds. Glaze can be poured inside vessels, held for the appropriate amount of time, then the glaze poured back into the bucket. Do not dip ware multiple times to build up a thicker layer of glaze. For a thicker layer of glaze, hold the ware in the glaze bucket for a longer period of time. The appropriate coating of raw glaze (dry, before firing) should be at least the thickness of a dime, or 1.5 millimeters. Thicker or thinner coatings of glaze may not give the desired effects when fired.

TROUBLESHOOTING GUIDE

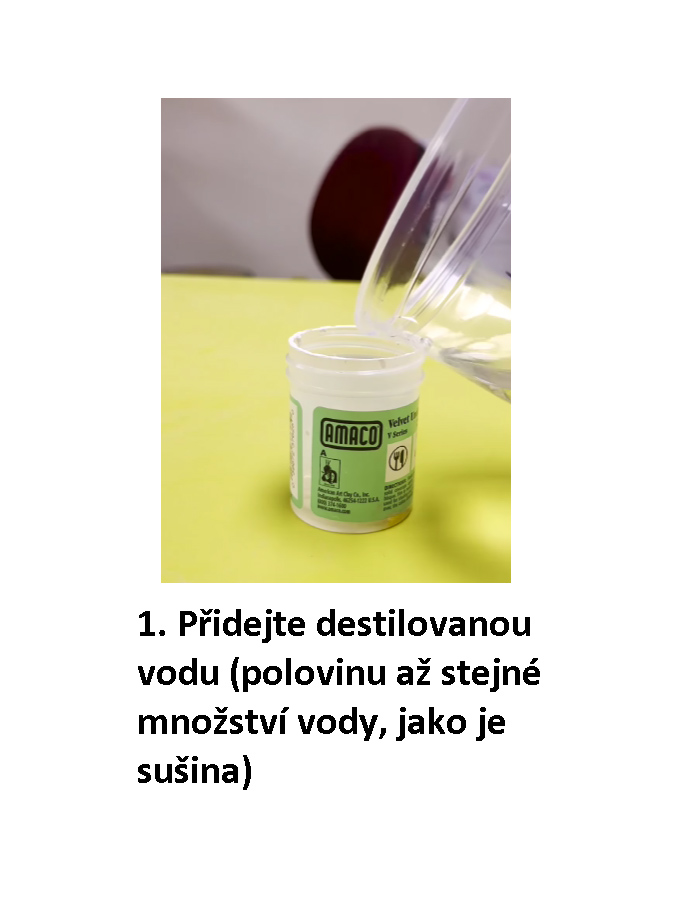

WATER QUALITY

We recommend using distilled water for mixing AMACO dry form dipping glazes. Tap water may contain soluble salts which can cause glazes to clump and settle or gel. Reverse osmosis or filtered water is not a substitute for distilled water. Softened water can cause glazes to appear thinner and eventually settle or “hardpan”.

LAYERING

AMACO layering brochures show layering of brushing glazes. AMACO Dry form glazes for dipping are meant to be used as a single application, not layered. Layering dipping glazes is not recommended because multiple dips of glaze may cause the initial coating of glaze to lose adhesion. When this happens the glaze may crack and peel before firing, and flake off the ware or crawl during firing. Some potters have had great results with layering dipping glazes. Our best recommendation for layering the dipping glazes is to make the second dip of glaze as soon as the first dip is dry to the touch – firm but still cool (slightly damp). Also, minimizing the area of overlap can help avoid peeling and crawling.

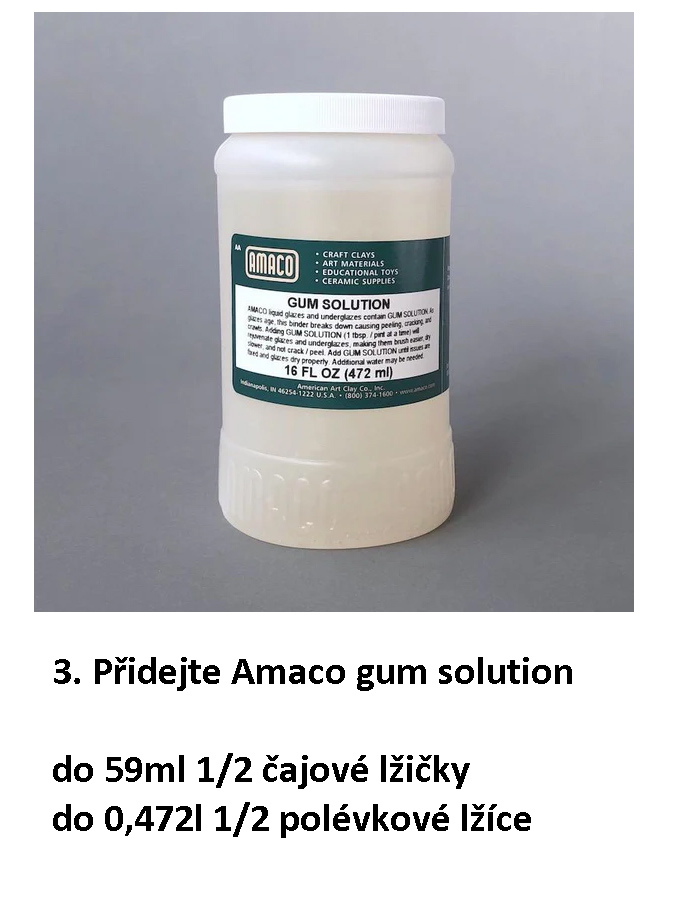

HARD-PANNING OR SETTLING

If your glaze settles to the bottom of the bucket in a hard layer (hard-pans) thoroughly mix the glaze with a high-speed mixer for an additional 15 minutes. If it continues to hard-pan, AND your specific gravity is correct, add one cup (8 fl oz or 237 ml) of AMACO Suspendaid to the bucket of glaze, mix with a high-speed mixer for at least 10 minutes and let sit overnight. If the glaze continues to hardpan, contact AMACO Customer Care for additional support. *

is reached.

If your glaze specific gravity is lower than the recommended range, leave the glaze to settle overnight, remove some of the water from the top of the glaze and set aside. Blend the glaze well and check the gravity again.

BACK