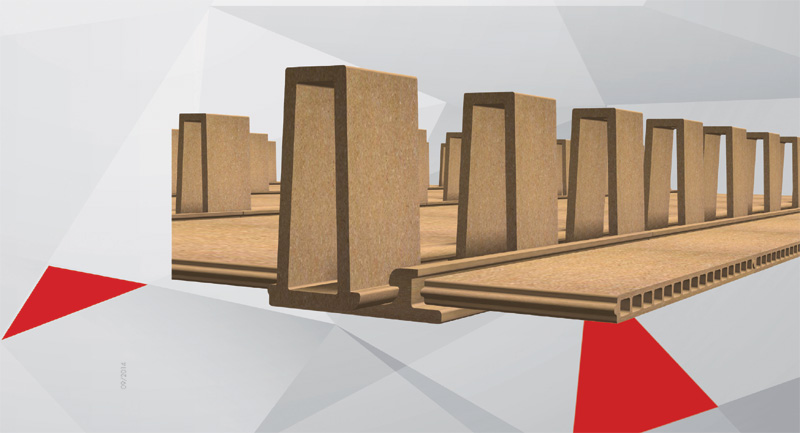

... Ceramic slabs from ICRA company

Ceramic slabs are manufactured by ICRA company in Italy. ICRA is a leading manufacturer of ceramic rollers, refractory supports, special parts and products in silicon carbide.

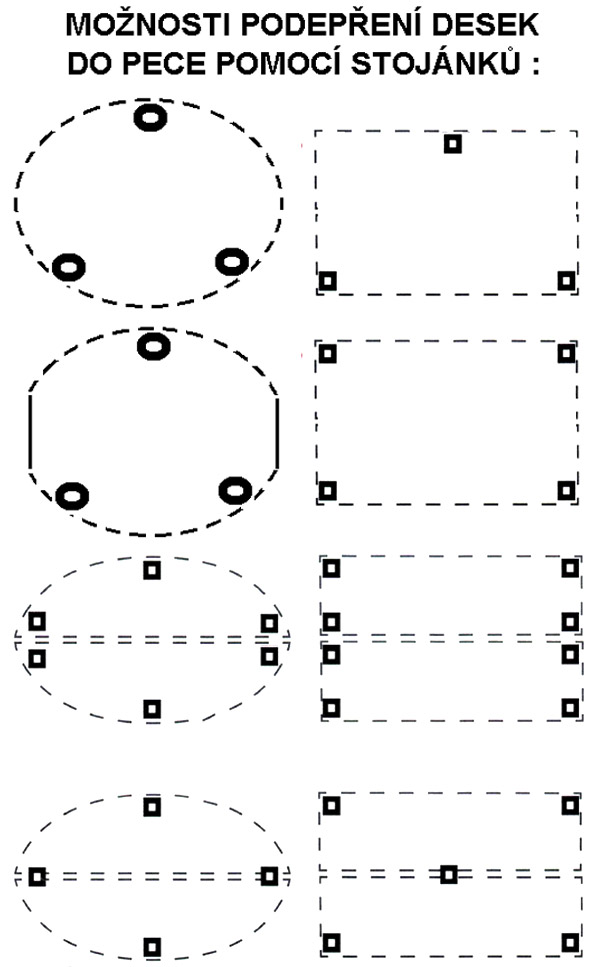

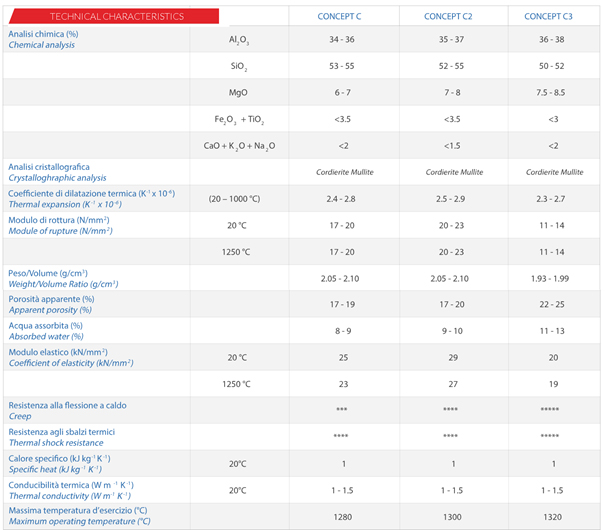

Ceramic slabs must be selected according to the amount of firing temperature, firing curve, load and process for using. Slabs must be properly dried, use only suitable coatings, prevent thermal shocks.

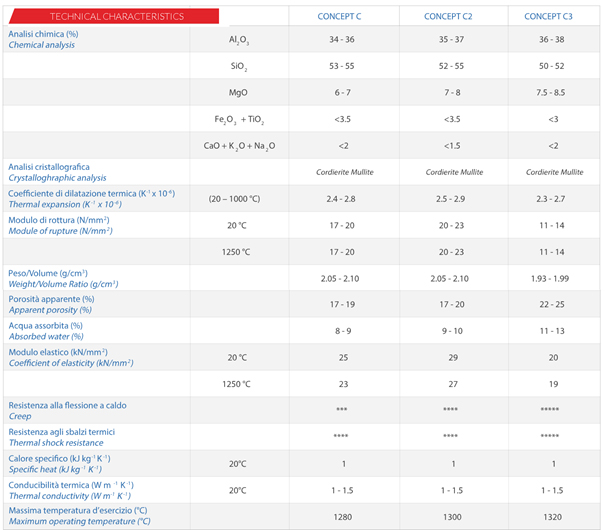

Propec company guarantees that the board material complies with the manufacturer's technical data sheets for materials C, C2 and C3. Propec does not guarantee the choice of size, type and kind of boards ordered. If you do not have experience with this, we will be happy to advise you. For larger dimensions and larger loads, larger floors, we recommend greater board thickness. Here it is necessary to choose a compromise between durability, price and energy consumption.

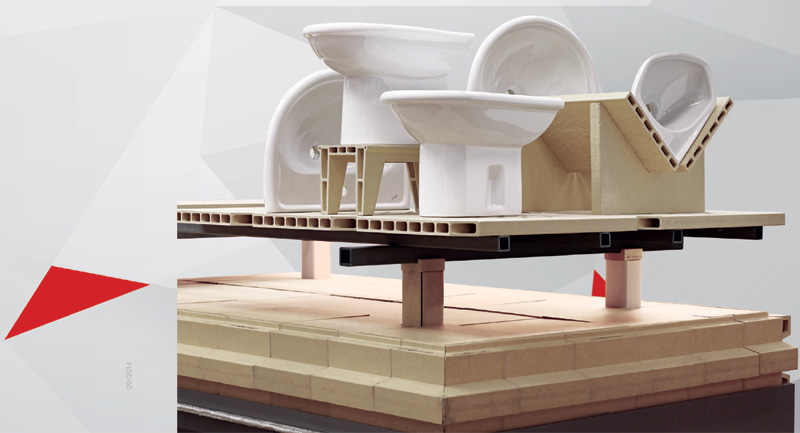

CONCEPT C

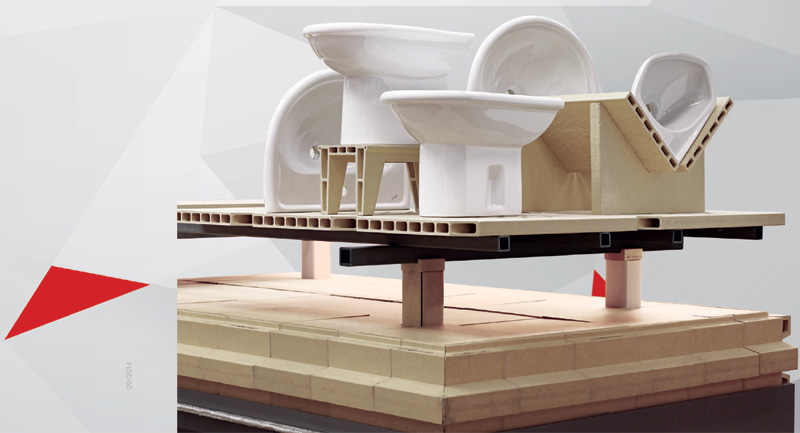

This type of formula is particularly suitable for firing sanitary ware in roller kilns, thanks to its excellent resistance to thermal shock.

CONCEPT C2

This is ICRA’s most used refractory formula. C2 products are used by a great number of sanitary fittings manufacturers throughout the world. They offer countless advantages, including the lightness and resistance of the material.

CONCEPT C3

This is the formula recommended for the most critical situations. Its main feature is that it offers greater refractoriness, thereby enabling large loads to be fired without having to increase the size of the refractory support. It is also suitable for manufacturing the columns required for the complex superstructures of kiln cars.

High resistance to thermal shock

- Greater heating and cooling rates with resulting energy savings

- Greater homogeneity of temperature in the slab

- Excellent performance during firing at high temperature

- Less thermal Δ between the support and piece being fired

- Absolute precision

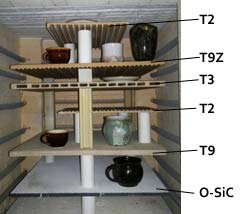

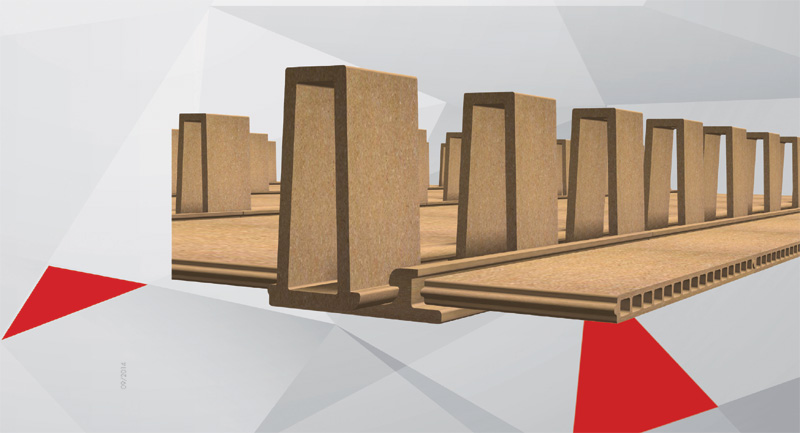

ICRA has produced a vast range of setter slabs (T2 - T3 - T9 - T9Z) for firing art ceramics, crockery, mosaics and special items. The specific development of the mixes has made it possible to offer the market very thin setter slabs with special profiles.

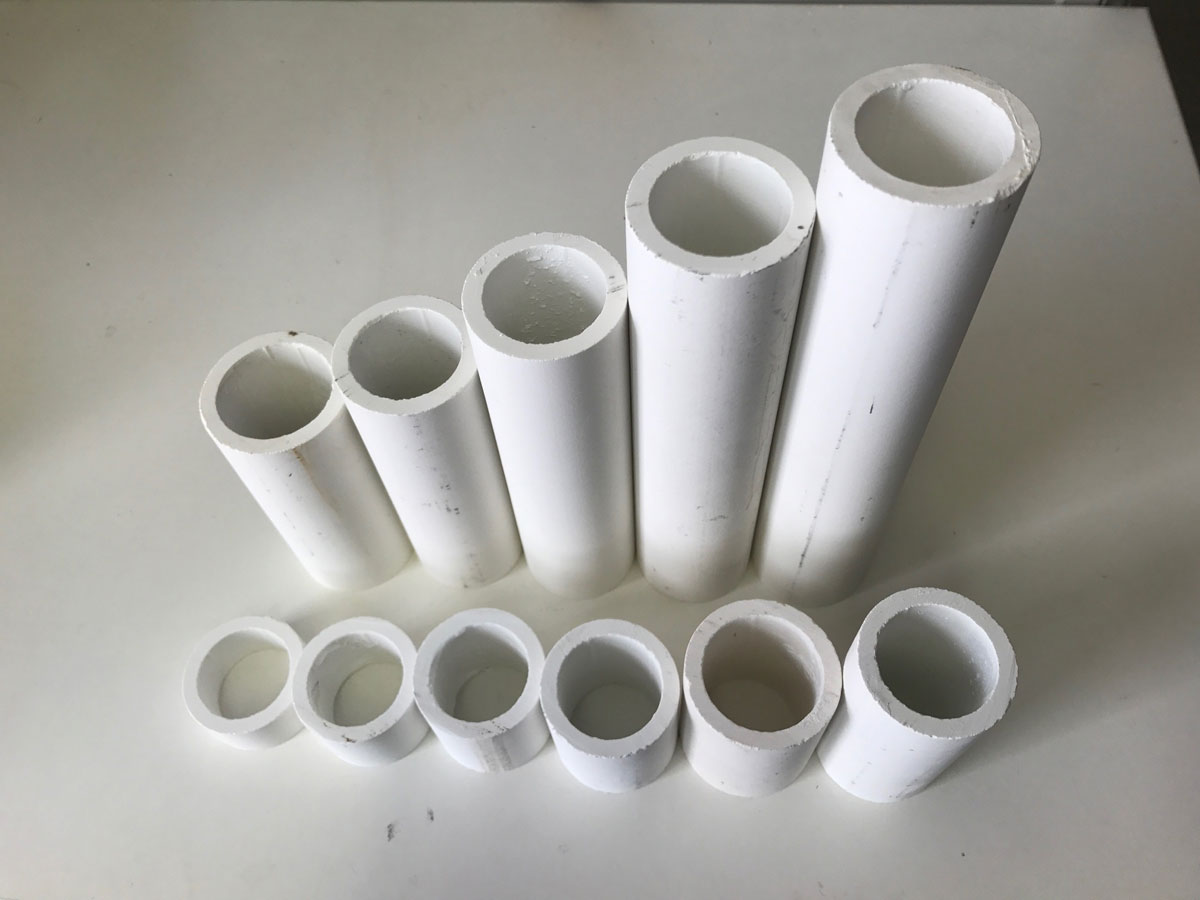

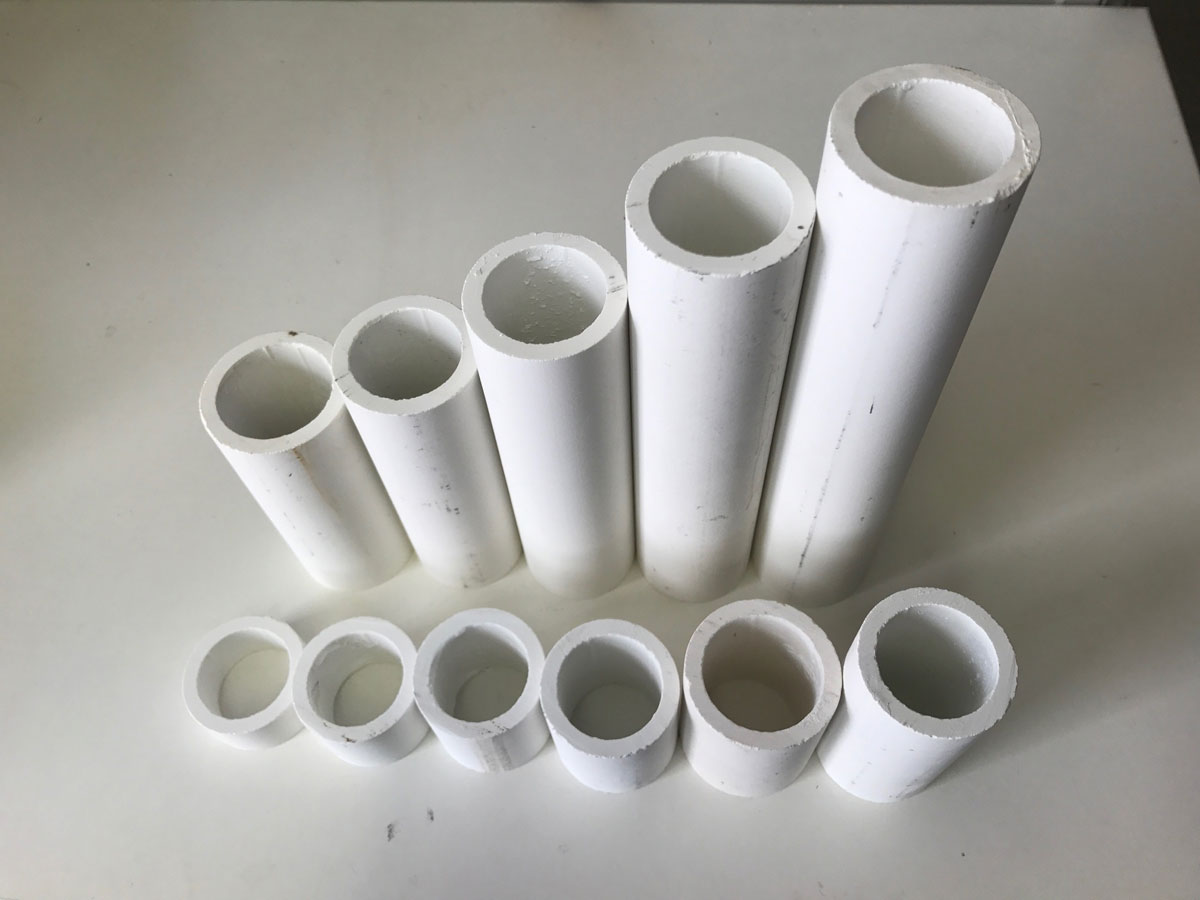

... Props are made from roller Pyrolax 50 or HT.

1) PYROXAL® 50

The specific mineral composition, micro-structure and porosity of Pyroxal® 50 have been studied to provide excellent resistance to chemical aggression, reducing matrix vitrification induced by the presence of vapours in kilns. Pyroxal® 50 has medium-high density values, a low thermal expansion coefficient ratio, excellent resistance to hot bending strength and sudden temperature changes. The special porosity with characteristic low total pore area values guarantees that residue left by the tile does not adhere to the roller surface making it last longer. These characteristics make Pyroxal® 50 just the right roller to work in conditions in which it is needed an elastic modulus higher than the one of a standard roller.

2) PYROXAL® HT

Pyroxal® HT is the answer to the market need for technical and much wider kilns for the production of tiles with demanding size tolerances. Roller rigidity due to the really high elasticity modulus and excellent resistance to bending at high temperatures allow the Pyroxal® HT to work under heavy loads and at high firing temperatures.

3) Also we made H props from second-hand slabs T3

Quality Pyroxal material can be recognized, among other things, by the fact that the props has notches in inside!!! (see in photo)

Sample of H props + props dim.42

... Ceramic rollers from Icra company

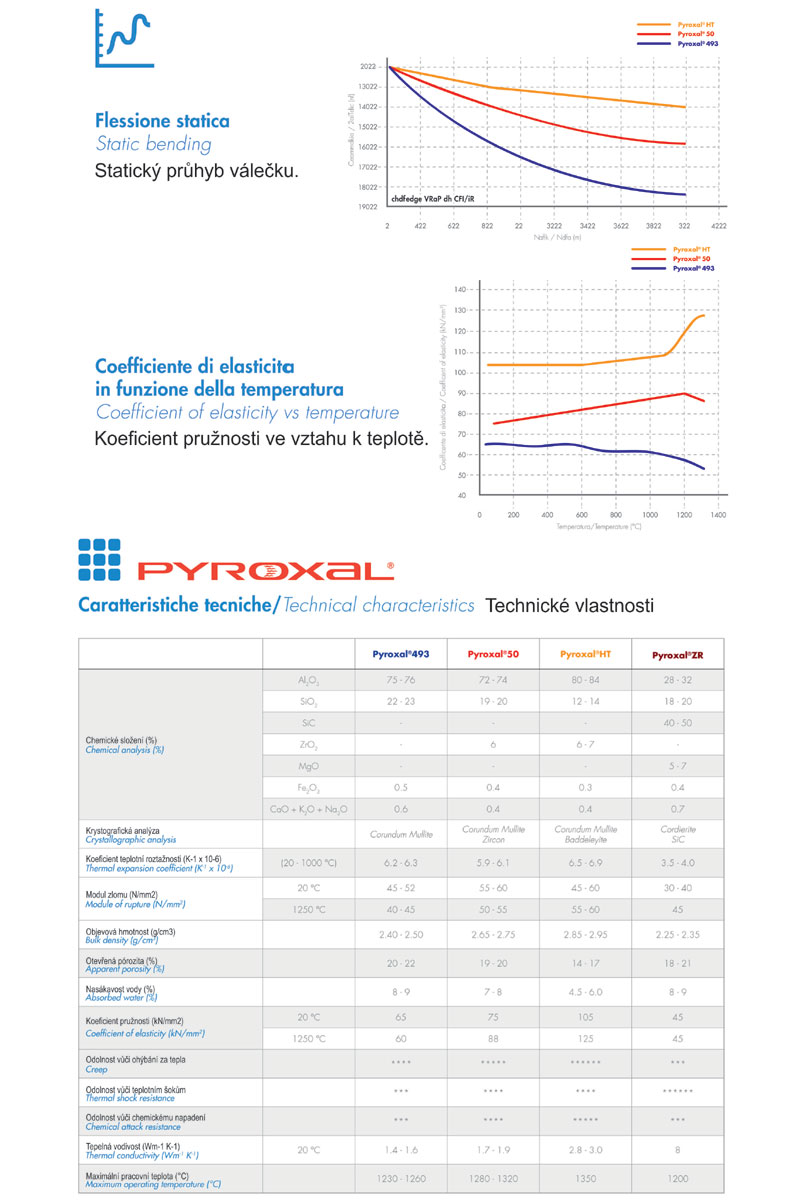

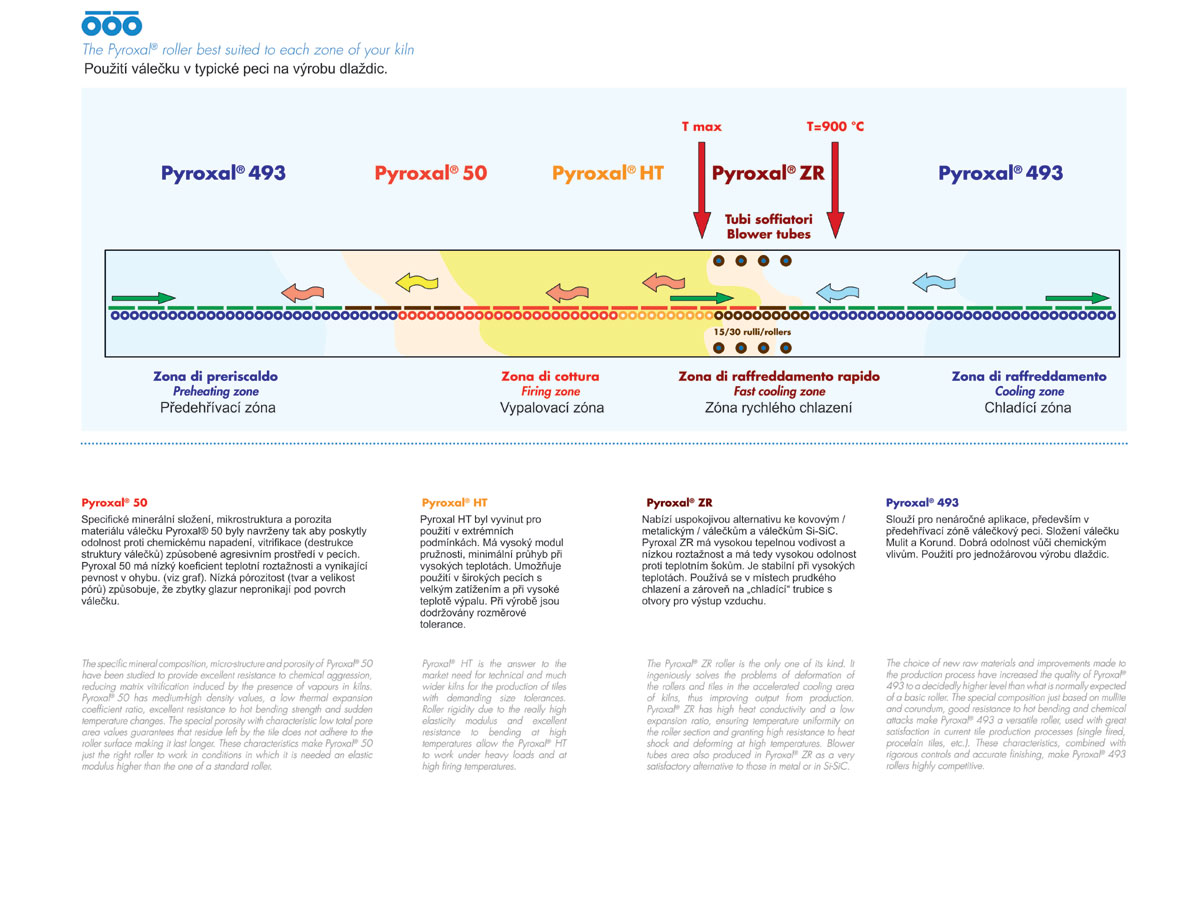

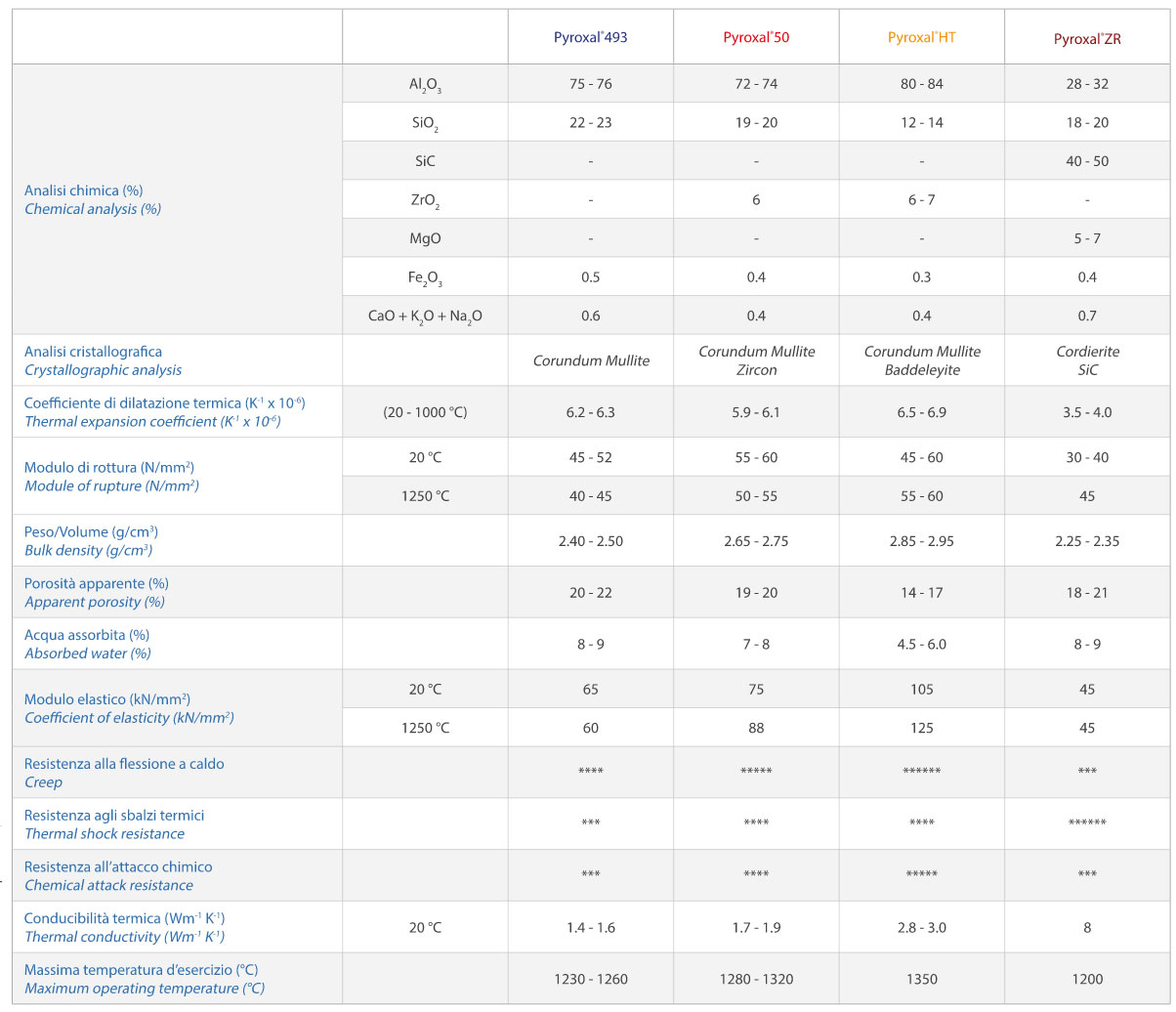

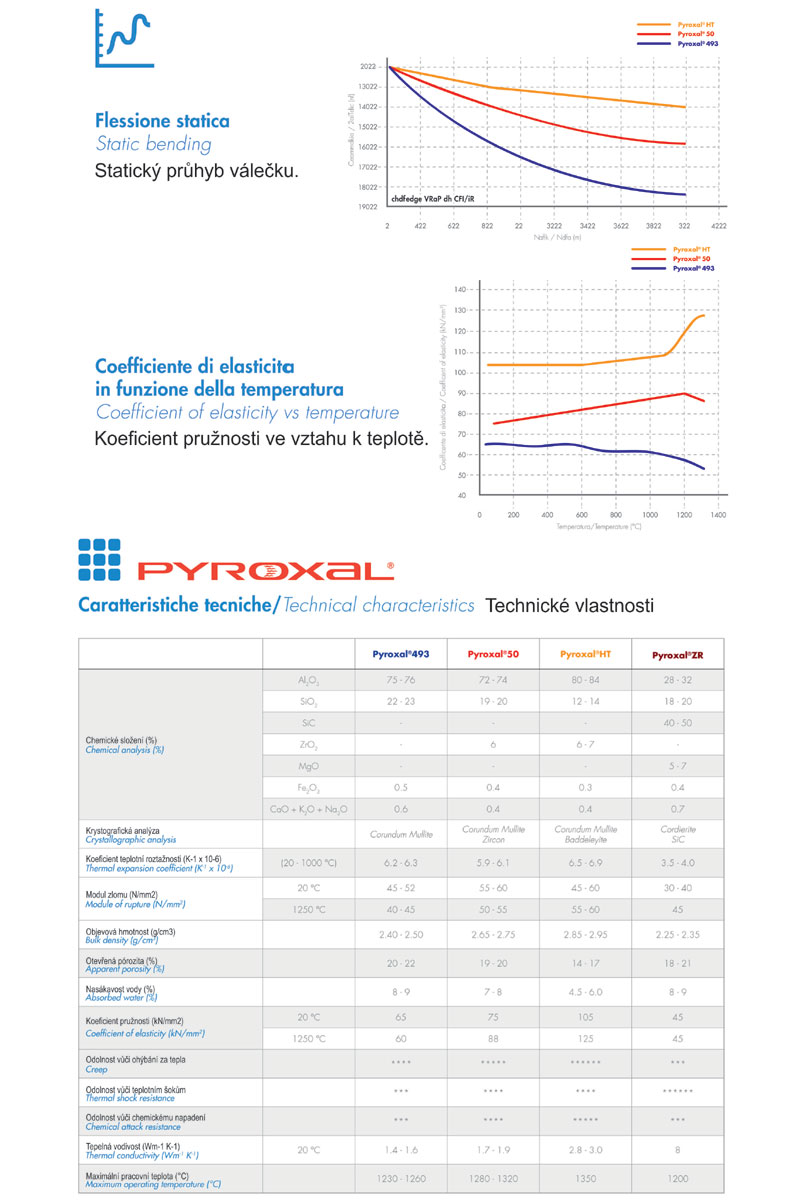

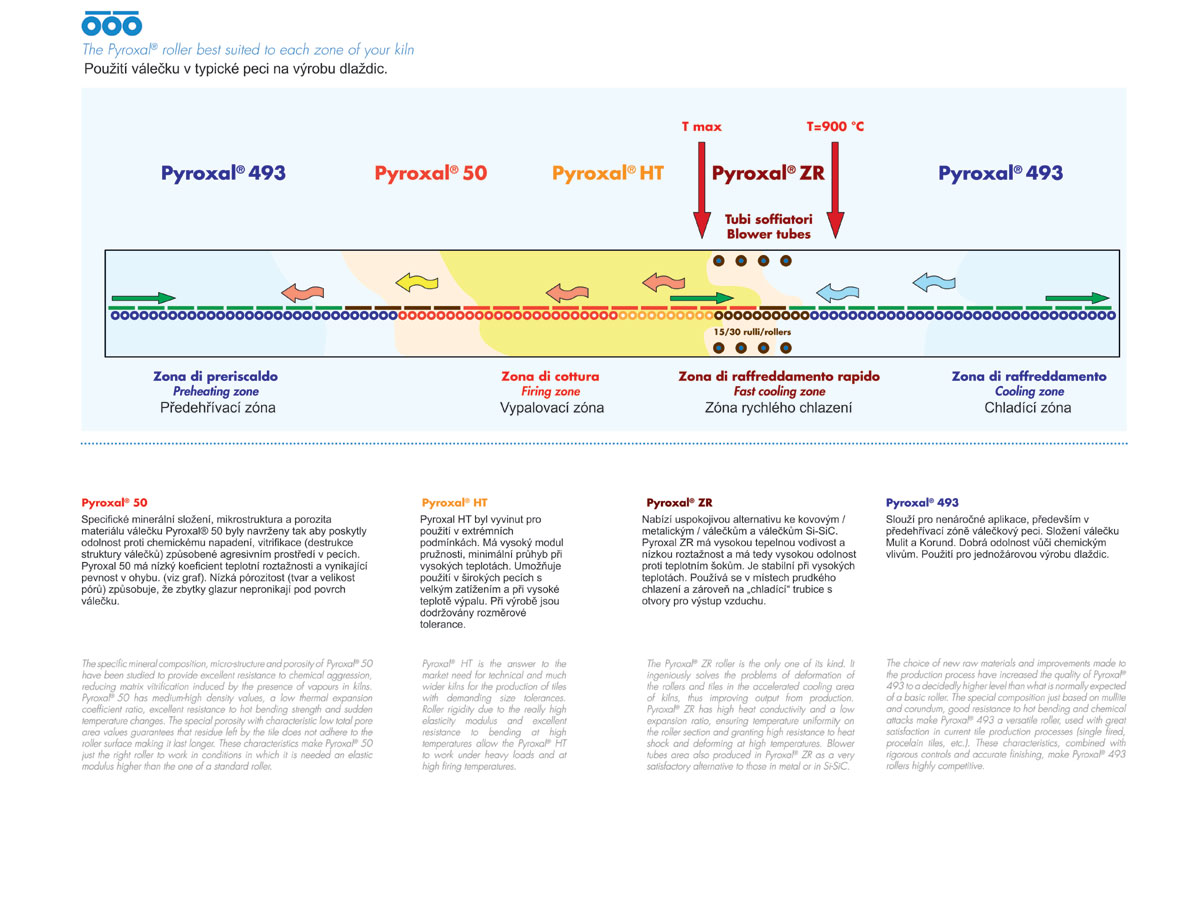

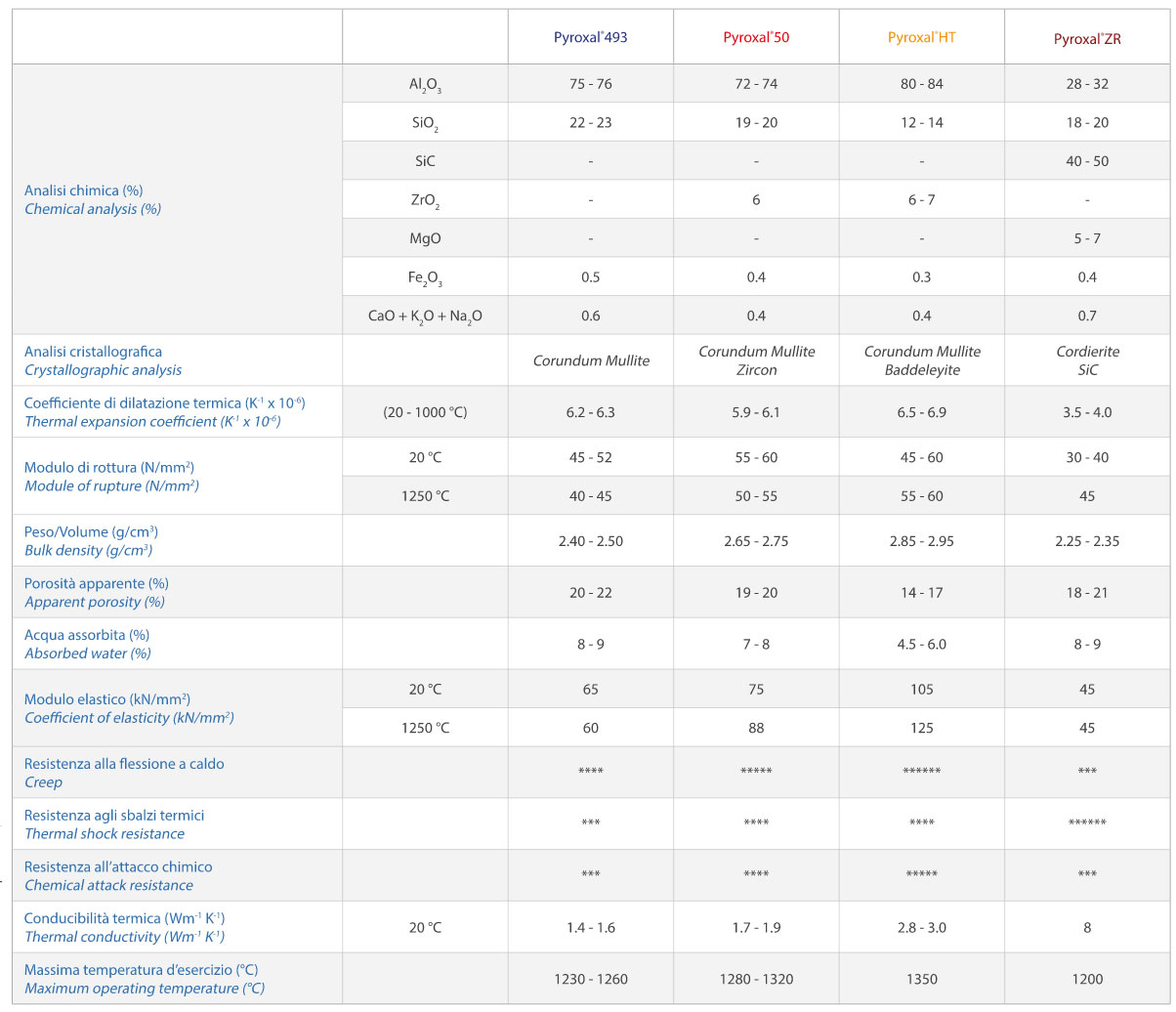

Pyroxal® 50, Pyroxal® HT ceramic rollers, ICRA has studied formulas with chemical-physical characteristics that specifically qualify them to be used in each zone of your kiln, enabling work to be done in maximum safety, increasing product yield and decreasing the need for maintenance.

PYROXAL® 50

The specific mineral composition, micro-structure and porosity of Pyroxal® 50 have been studied to provide excellent resistance to chemical aggression, reducing matrix vitrification induced by the presence of vapours in kilns. Pyroxal® 50 has medium-high density values, a low thermal expansion coefficient ratio, excellent resistance to hot bending strength and sudden temperature changes. The special porosity with characteristic low total pore area values guarantees that residue left by the tile does not adhere to the roller surface making it last longer. These characteristics make Pyroxal® 50 just the right roller to work in conditions in which it is needed an elastic modulus higher than the one of a standard roller.

PYROXAL® HT

Pyroxal® HT is the answer to the market need for technical and much wider kilns for the production of tiles with demanding size tolerances. Roller rigidity due to the really high elasticity modulus and excellent resistance to bending at high temperatures allow the Pyroxal® HT to work under heavy loads and at high firing temperatures.

TECHNICAL DATA

Note: The technical data shown are indicative and they have been drown, where possible, from official standard or from standard internal tests. They serve to give general information, they are liable to natural deviations, depending on production and shape and they are not to be cited as guaranteed properties or guaranteed values and can be changed without notice.

THE PYROXAL® ROLLER BEST SUITED TO EACH ZONE OF YOUR KILN