Reaction-bonded Silicon Carbide- RBSIC(SiSiC)

This is reaction-bonded (silicon infiltrated) silicon carbide, being formed zero porosity by filling up open porosity with silicon metal (Si). Because of it's zero porosity characteristic, thermal conductivity is more than twice of Oxide Bonded SiC's, bending strength is more than 5 times higher comparing to Oxide Bonded SiC. RBSIC(SiSiC)'s special feature is its ability to maintain high strength from room temperature up to 1,350°C. Also it has very high oxidation resistance, chemical resistance and wear resistance. Used as beam, roller, radiant tube burner and burner nozzle etc.

Specifications

|

Item

|

Unit

|

Index

|

|

Application temperature

|

℃

|

1380

|

|

Density

|

g/cm3

|

≥ 3.02

|

|

Open porosity

|

%

|

≤ 0.1

|

|

Bending strength

|

Mpa

|

250 (20℃)

|

|

Mpa

|

280 (1200℃)

|

|

Modulus of elasticity

|

Gpa

|

330 (20℃)

|

|

Gpa

|

300 (1200℃)

|

|

Thermal conductivity

|

W/m.k

|

45 (1200℃)

|

|

Coefficient of thermal expansion

|

K-1×10-6

|

4.5

|

|

Rigidity

|

|

13

|

|

Acid and alkali resistance

|

|

Excellent

|

|

SiC

|

%

|

>90

|

|

Si

|

%

|

<10

|

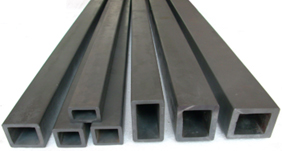

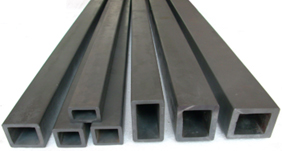

1) Beams RBSIC(SiSiC): RBSIC(SiSiC)

We have cross beam, solid beam and special shape beam. Reaction-bonded silicon carbide beam is applied to the bearing frame of tunnel furnace, shuttle furnace and industrial furnace. reaction-bonded silicon carbide beam is characterized by big high-temperature resistance, no bending deformation and long service life, and is an ideal furnace applied to sanitary ceramics and electro ceramics furnaces. reaction-bonded silicon carbide, with good thermal conductivity, can save energy consumption significantly. The Bending Strength of RBSIC(SiSiC) Beams is 250MP, safety coefficient is 5. Concentrated Loading =the Value in the Table Accordingly x 1/L. Uniformly Distributed Loading = the Value in the Table Accordingly x 1/L.

PRESS HERE

|

Bearing Capacity of RBSIC(SiSiC) Beams

|

|

Size of Section (mm)

|

Wall Thickness(mm)

|

Concentrated Loading (kg.m/L)

|

Uniformly Distributed Loading(kg.m/L)

|

|

B Side

|

H Side

|

B Side

|

H Side

|

B Side

|

H Side

|

|

30

|

30

|

5

|

74

|

74

|

147

|

147

|

|

30

|

40

|

5

|

117

|

95

|

235

|

190

|

|

40

|

40

|

5 |

149

|

149

|

298

|

298

|

|

50

|

50

|

6

|

283

|

283

|

567

|

567

|

|

50

|

60

|

6

|

374

|

331

|

748

|

662

|

|

50

|

70

|

6

|

473

|

379

|

946

|

757

|

|

60

|

60

|

7

|

481

|

481

|

962

|

962

|

|

80

|

80

|

7

|

935

|

935

|

1869

|

1869

|

|

100

|

100

|

8

|

1708

|

1708

|

3416

|

3416

|

|

110

|

110

|

10

|

2498

|

2498

|

4997

|

4997

|

2) Roller RBSIC(SiSiC)

Reaction-bonded silicon carbide roller rod is applied to high-temperature burning zone of the roller furnace for domestic ceramics, sanitary ceramics, building ceramics, glass and magnetic materials, etc.

reaction-bonded silicon carbide roller rod is characterized by big high-temperature resistance and no bending deformation, and its service life is 10-15 times that of alumina ceramic rod.

The Bending Strength of RBSIC(SiSiC) Rollers is 250MP, safety coefficient is 5.

Concentrated Loading =the Value in the Table Accordingly x 1/L,

Uniformly Distributed Loading = the Value in the Table Accordingly x 1/L.

|

Loading Capacity of RBSIC(SiSiC) Rollers

|

|

Size of Section (mm)

|

Wall Thickness(mm)

|

Concentrated Loading (kg.m/L)

|

Uniformly Distributed Loading(kg.m/L)

|

|

30

|

5

|

43

|

86

|

|

35

|

5

|

63

|

126

|

|

38

|

5

|

77

|

154

|

|

40

|

6

|

97

|

194

|

|

45

|

6

|

130

|

260

|

|

50

|

6

|

167

|

334

|

|

60

|

7

|

283

|

566

|

|

70

|

7

|

405

|

810

|

3) Cold-Air Tube - RBSIC(SiSiC)

Reaction-bonded silicon carbide cold-air tube is applied to the cooling zone of the roller furnace.

Reaction-bonded silicon carbide cold-air tube is characterized by big quick-cooling/quick-heating resistance and no bending deformation, and its service life is more than 10 times that of stainless steel tube.

4) Nozzles Series - RBSIC(SiSiC)

- Atomizing Nozzle

- Liquid Column Nozzle

- Two-Way Nozzle

- Flame Nozzle - Flame Separator

5) Silicon Carbide Plate - RBSIC(SiSiC) desky

Reaction-bonded silicon carbide plate is applied to kiln furniture for sanitary ceramics and fine ceramics.

6) Heat Radiation Indirect Heating System – RBSIC(SiSiC)

RBSIC(SiSiC) Reaction-bonded silicon carbide heat exchange tube, reaction-bonded silicon carbide radiant tube inner tube and outer tube assembly, applied to heat radiation indirect heating system. Reaction-bonded silicon carbide heat radiation indirect heating system is applied to some industrial furnaces, such as roller furnace, bogie furnace, etc. in such industries as steel and iron, stainless steel and non-ferrous metals.

7) Case-Crucible - RBSIC(SiSiC)

Reaction-bonded silicon carbide case-crucible is applied to powder sintering, metal smelting, etc. in such industries as metallurgy, chemicals, glass, etc.

8) Wear-resisting barrels - RBSIC(SiSiC)

Reaction-bonded silicon carbide wear-resisting barrels are used for cyclone wear-resistant liner, instead of imported products, it has high strength, high wear resistance, good heat conduction performance.

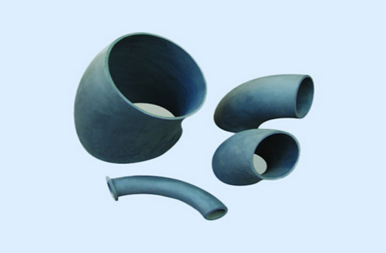

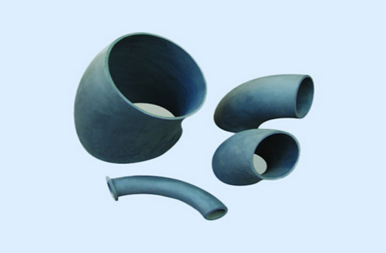

9) Elbow - RBSIC(SiSiC)

10) Taper Sleeve - RBSIC(SiSiC)

11) Irregular And Special-Shaped Silicon Carbide Ceramics RBSIC(SiSiC)